VDA KLT

VDA KLT

The VDA-KLT series is the go-to container lineup for uncomplicated, safe, and flexible (automatic or manual) handling of small standard parts and dangerous goods. VDA-KLT are made of shock-resistant PPC, with a base ribbing and stacking feet for tilt protection plus easy stacking. They are well suited for comfortable vertical and horizontal handling. Longitudinal- and front notches qualify these containers for use in automated small parts warehouses. A smooth texture on the inside simplifies the cleaning process. Due to these properties, the KLT series has an excellent reputation across many industries.

A closer look at the model numbers will give you a rough indication of the product dimensions (e.g., 3214 = approx. 300 mm x 200 mm x 140 mm). The exact details are included in the attached product data sheets.

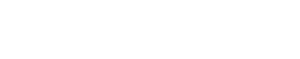

VDA KLT – 3214

The smallest container of the series, with an effective volume of 4,7 l. Due to the resilient nature of the material, it can handle payloads of up to 30 kg (66 lbs). Its internal dimensions are 260 x 136 x 144,9 mm / 9,8 x 5,35 x 5,7 in).

Features of the VDA KLT – 3214

- Great load capacity

- Automatable

- Great stacking capability

- Palette compatible

Usable volume

ca. 4,7 l

Net mass

0,79 kg

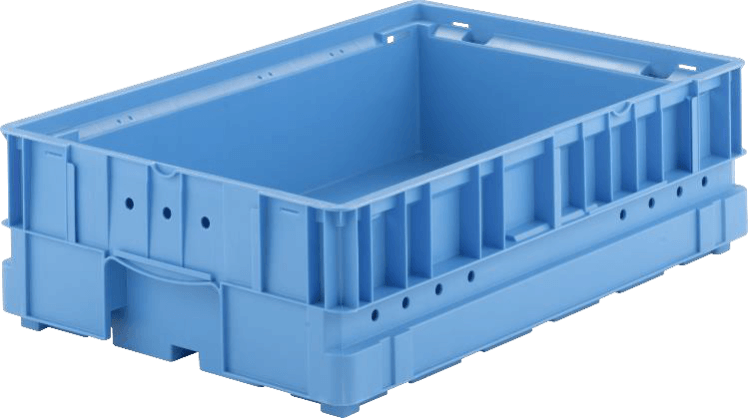

VDA KLT – 4314

The lowest container in the medium-sized 4000 series. Each 4000 series container has a usable internal dimension of 334 x 247 mm (length, width) with increasing height depending on the model number. The maximum payload of all 4000 KLTs is 50 kg. Due to the low form factor, 120 boxes fit on one pallet.

Features of the VDA KLT – 4314

- Great load capacity

- Automatable

- Great stacking capability

- Palette compatible

Usable volume

ca. 8,7 l

Net mass

1,8 kg

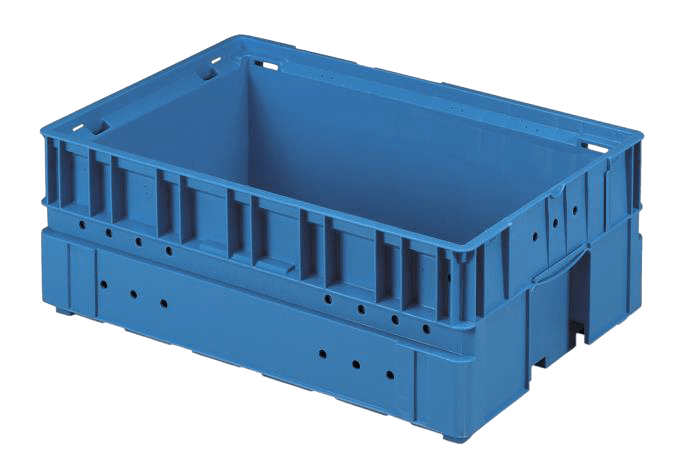

VDA KLT – 4321

A mid height mid volume small load carrier. Stackable, automatable, and 66 mm (2,5 in) higher than its smaller equivalent, with an effective volume of 14,2 l.

Features of the VDA KLT – 4321

- Great load capacity

- Automatable

- Great stacking capability

- Palette compatible

Usable volume

ca. 14,2 l

Net mass

2,2 kg

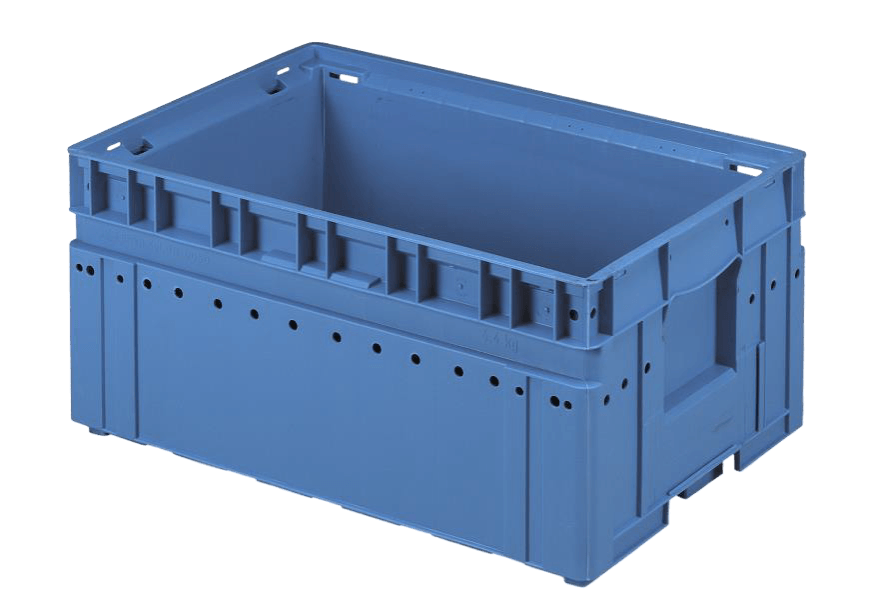

VDA KLT – 4328

Another 66mm higher than its smaller brother granting it an effective volume of 19,6 l.

Features of the VDA KLT – 4328

- Great load capacity

- Automatable

- Great stacking capability

- Palette compatible

Usable volume

ca. 19,6 l

Net mass

2,8 kg

VDA KLT – 6414

The 6000 series has a standardized length and width of 532 x 346 mm (20,9 x 13,6 in), making it especially useful for storing long parts and goods. The 6414 is the lowest container in this lineup, with a height of 147,5 mm (5,8 in) and an effective volume of 18,5 l.

Features of the VDA KLT – 6414

- Great load capacity

- Automatable

- Great stacking capability

- Palette compatible

Usable volume

ca. 18,5 l

Net mass

2,4 kg

VDA KLT – 6417

The usable internal space of this load carrier is about 12 mm higher than its smaller brother, giving it an additional 5 l of effective volume (23,4l).

Features of the VDA KLT – 6417

- Great load capacity

- Automatable

- Great stacking capability

- Palette compatible

Usable volume

ca. 23 l

Net mass

3,6 kg

VDA KLT – 6421

Another additional 7 l of volume (30, 7 l), with a usable internal space that measures 532 x 346 x 181,8 mm (20,9 x 13,6 x 7,1 in).

Features of the VDA KLT – 6421

- Great load capacity

- Automatable

- Great stacking capability

- Palette compatible

Usable volume

ca. 30,7 l

Net mass

4,3 kg

VDA KLT – 6428

The largest KLT (small load carrier) boasts a massive volume of 42,9 l, while its external dimensions remain fairly handy (594 x 396 x 280 mm or 23,4 x 15,6 x 11 in).

Features of the VDA KLT – 6428

- Great load capacity

- Automatable

- Great stacking capability

- Palette compatible

Usable volume

ca. 42,9 l

Net mass

5 kg

VDA KLT – General Information

KLT is the German abbreviation for “Kleinladungsträger“, meaning small load carrier. A VDA KLT thereby is a compact VDA-compliant load carrier. The KLT-series is well suited for automatic and manual handling across multiple industries. Stored in one of these containers, standard parts, and dangerous goods will reach their destination safely.